H Frame Servo Guide Stamping Hydraulic Press Machine

This Frame Servo Guide Precision Hydraulic Molding Press Machine was mainly applies to stretch forming large products,such as automobile panels,interior parts,TV shell,computer case,kitchen stainless steel sink etc.

Brand Name: GOODSJACK

Model number: GSJ-DKLS

Product Type: Servo Guide Stamping Press

Payment Terms: T/T,L/C

Package: Wrapping film and metal packing

Minimum Order: 1 set

Delivery Time: 45-70 working days

Place of origin: China

Price Terms: FOB, CIF

Detail

H Frame Servo Guide Stamping Hydraulic Press Machine characteristics

Frame structure: welded frame structure made of high quality steel plate and annealing process, confirm the elastic deformation in maximum pressure through finite element analysis, guiding of moving bolster by eight-face linear guide way, enhance the stability of moving bolster movement and high eccentric pressing force.

Ease operation: user friendly HMI, ease for setting parameters and recipe storage.

Control system: PLC + HMI (Siemens brand), refers to pressing technology requirement set the parameters on HMI such as pressure, position, hold pressure, multi-pressing, etc.

Accuracy monitoring: used for linear scale and pressure sensor to monitor the position and pressure, enhance the pressing accuracy.

Position accuracy: repeatability of ram position achieved to ±0.02mm, control the scrap rate of products caused by machine accuracy.

Pressing accuracy: repeatability of ram pressure achieved to ±3%, control the scrap rate of products caused by machine accuracy.

Energy saving: high power motor fulfill high speed high pressure processing requirements, servo motor driving system can achieve energy saving of 40 – 60%.

Low noise level: used of servo motor driving system, fulfills different speed and pressure of pressing requirements, ensures the stability of movement, lower noise level.

Ram cylinder designed: used of forged steel and its inner surface is finely grinded, prolonging working life under high pressure.

Hydraulic circuit designed: used of advance two-way cartridge valve, high reliability and less impact on changing of different pressing stage.

Ease for maintenance: module structure designed as different function requirements, ease to dis-assembly, machine problems can be checked on HMI.

Automation: design of different automatic production equipment as customers requested.

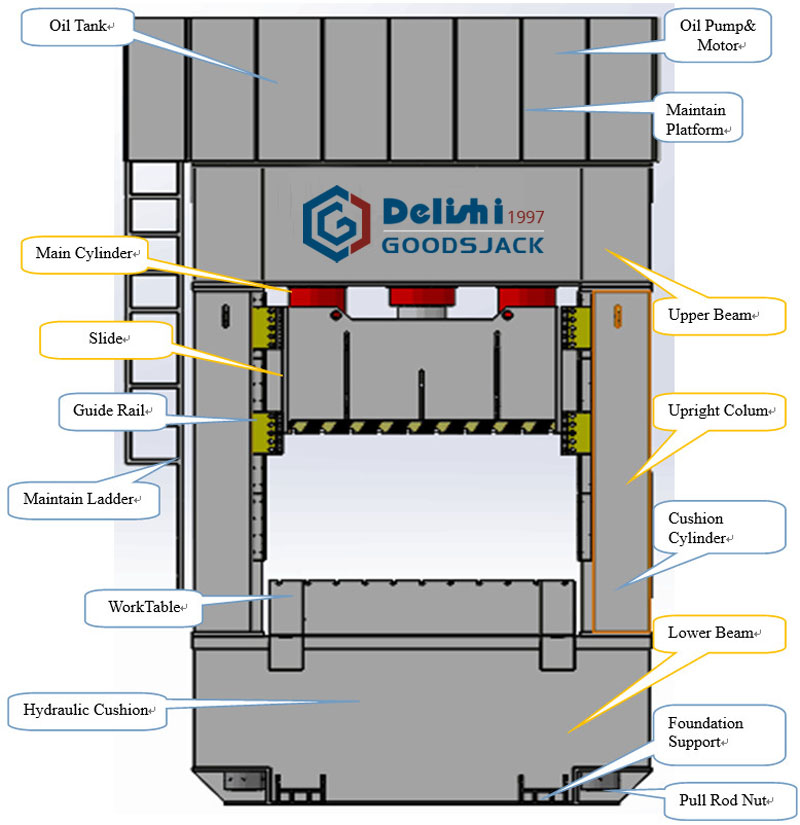

H frame hydraulic press machine structure and composition

![]()

Mainly applies to stretch forming large products,such as automobile panels,interior parts,TV shell,computer case,kitchen stainless steel sink etc.

![]()

| Model | Units | Specifications | |||||||||||

| DKLS-300 | DKLS-400 | DKLS-500 | DKLS-600 | DKLS-600L | DKLS-800 | DKLS-800L | DKLS-1000 | DKLS-1200 | DKLS-1600 | DKLS-2000 | |||

| Master cylinder |

Capacity | ton | 300 | 400 | 500 | 600 | 600 | 800 | 800 | 1000 | 1200 | 1600 | 2000 |

| Stroke | mm | 400 | 400 | 400 | 400 | 700 | 700 | 700 | 700 | 700 | 700 | 700 | |

| Down Speed | mm/s | 210 | 210 | 210 | 210 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | |

| Press speed | mm/s | 24-12 | 18-9 | 15-7 | 12-6 | 12-26 | 10-25 | 10-22 | 10-22 | 10-20 | 8-18 | 8-15 | |

| Return speed | mm/s | 180 | 180 | 180 | 180 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | |

| System pressure | bar | 240 | 240 | 240 | 240 | 240 | 250 | 250 | 250 | 250 | 250 | 250 | |

| Open height | mm | 700 | 700 | 700 | 700 | 1000 | 1200 | 1200 | 1200 | 1200 | 1200 | 1400 | |

| Working table height | mm | 850 | 850 | 900 | 900 | 1200 | 1400 | 1400 | 1500 | 1500 | 1600 | 1800 | |

| Working table size |

L-R(Inner) | mm | 1600 | 1600 | 1600 | 1600 | 2200 | 2200 | 2800 | 2800 | 2800 | 2800 | 2800 |

| F-B(Edge) | mm | 1000 | 1000 | 1000 | 1000 | 1500 | 1500 | 1800 | 1800 | 1800 | 1800 | 1800 | |

| Motor power | kw | 34.6 | 34.6 | 34.6 | 42 | 34.2 | 45.2 | 45.2 | 47.2 | 47.2 | 50.2 | 55.2 | |

| Machine size | L-R | mm | 2850 | 2850 | 2950 | 2950 | 3598 | 4200 | 5000 | 5300 | 5300 | 5300 | 5600 |

| F-B | mm | 2140 | 2140 | 2140 | 2140 | 3510 | 3010 | 3500 | 3500 | 3500 | 3500 | 4000 | |

| H | mm | 3770 | 3770 | 3870 | 3870 | 4590 | 5500 | 5500 | 5500 | 5500 | 5500 | 6000 | |

![]()

![]()