Servo Frame Rail Deep Drawing Hydraulic Press

Our frame rail deep drawing press applicable to tableware,kitchenware,lighting radiators and other metal products,deep drawing molding.Our standard deep drawing press ranges in tonnage from 50 to 1200 tons, features compact and intuitive design. Model number: GSJ-DKFS

Product Type: Servo Deep Drawing

Payment Terms: T/T,L/C

Package: Wrapping film and metal packing

Minimum Order: 1 set

Delivery Time: 35-60 working days

Place of origin: China

Price Terms: FOB,C&F,CIF

Detail

Servo Frame Rail Deep Drawing Hydraulic Press Machine

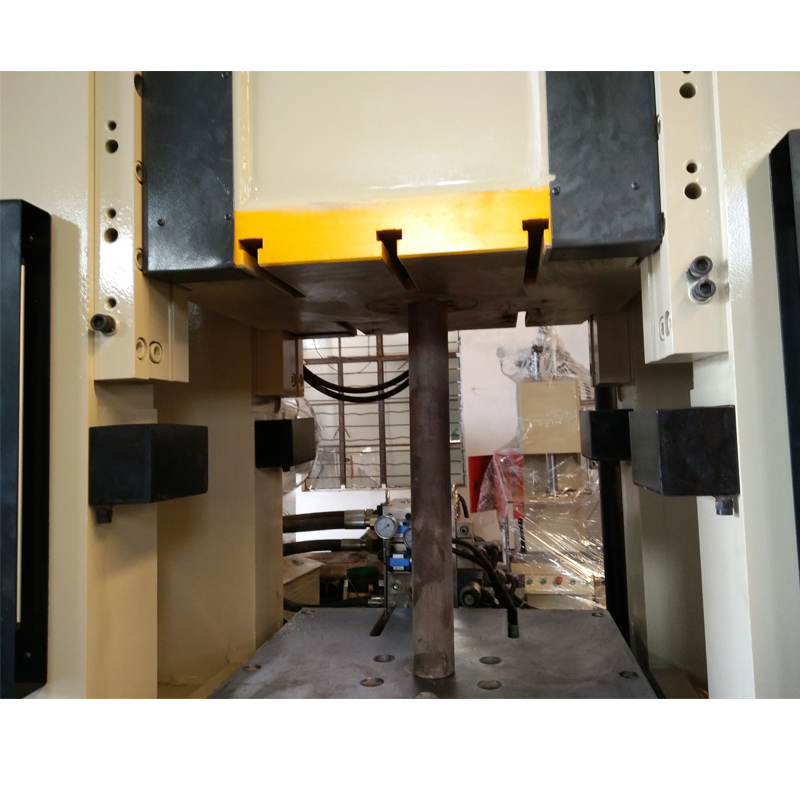

Our standard deep drawing press ranges in tonnage from 50 to 2000 tons, features compact and intuitive design, function with either single action or double action deep drawing process. This frame guide deep drawing press is double action structure. Heavy frame and stress-relieved frame body are extremely rigid and minimum deflection to provide perfect rigidity and durability. Well-forged and precise-polished heavy-duty cylinder remain highly reliable when machine running at the high load condition.

Unique to our deep draw hydraulic press is that the pressure output of deep drawing press machine is dynamically changing due to the pressure proportioning function of the main cylinder and lower blank hold cylinder. The main cylinder pressure proportioning can reduce the loss of force during the drawing process so. The lower cylinder pressure proportioning can reduce the force of blank holding along with the change of drawing height and blank holding size. This optional function allows our customers to achieve maximum productivity and minimum rejection rate.

Our engineers can design and drawing the machine drawing according to customers' requirements. Such as linking automation production line. Any interest and requirements, please tell us in advance, then best suitable hydraulic press drawing will be supplied to you!

Applicable to tableware,kitchenware,lighting radiators and other metal products,deep drawing molding.

| Model | Units | Specifications | ||||||||||||

| DKFS-50 | DKFS-75 | DKFS-120 | DKFS-150 | DKFS-220 | DKFS-220L | DKFS-275 | DKFS-350 | DKFS-350L | DKFS-500 | DKFS-500L | DKFS-600 | |||

| master cylinder |

rated capacity |

ton | 35 | 50 | 85 | 100 | 160 | 160 | 200 | 260 | 260 | 350 | 350 | 420 |

| stroke | mm | 350 | 450 | 450 | 560 | 560 | 560 | 560 | 560 | 560 | 600 | 600 | 700 | |

| fast dowm speed |

mm/s | 210 | 220 | 220 | 220 | 230 | 230 | 220 | 190 | 190 | 230 | 230 | 210 | |

| coining speed |

mm/s | 20-40 | 20-40 | 20-40 | 21 | 20-40 | 22-40 | 20-40 | 15-30 | 15-30 | 15-30 | 15-30 | 14-28 | |

| return speed |

mm/s | 190 | 220 | 220 | 180 | 220 | 220 | 210 | 165 | 165 | 170 | 170 | 190 | |

| system pressure | bar | 220 | 220 | 220 | 240 | 240 | 240 | 240 | 230 | 230 | 240 | 240 | 230 | |

| cylinder pressure side |

blank holder force |

ton | 15 | 25 | 35 | 50 | 60 | 60 | 75 | 90 | 90 | 150 | 150 | 180 |

| stroke | mm | 175 | 200 | 200 | 260 | 260 | 260 | 260 | 260 | 260 | 300 | 300 | 350 | |

| unloading cylinder |

ejecting force | ton | 2 | 3 | 5 | 5 | 5 | 5 | 5 | 10 | 10 | 10 | 10 | 10 |

| stroke | mm | 150 | 180 | 180 | 200 | 200 | 200 | 200 | 220 | 220 | 250 | 250 | 300 | |

| open thight(slide to bolster) | mm | 600 | 730 | 730 | 750 | 900 | 1000 | 900 | 900 | 900 | 1000 | 1200 | 1500 | |

| working table size |

L-R | mm | 500 | 500 | 600 | 600 | 710 | 900 | 800 | 900 | 1100 | 1050 | 1250 | 1400 |

| F-B | mm | 550 | 600 | 600 | 800 | 870 | 1100 | 900 | 1000 | 1250 | 1200 | 1500 | 1600 | |

| bolster height | mm | 850 | 950 | 1000 | 1000 | 1080 | 1100 | 1100 | 1150 | 1150 | 1350 | 1350 | 1500 | |

| main motor power | KW | 8.6 | 8.6 | 16 | 24 | 35 | 35 | 35 | 37 | 37 | 55 | 55 | 55 | |

| over all dimension |

L-R | mm | 1350 | 1400 | 1420 | 1430 | 1750 | 1900 | 1800 | 3020 | 3250 | 3310 | 3510 | 3700 |

| F-B | mm | 1530 | 1580 | 1680 | 1880 | 2200 | 2530 | 2250 | 2200 | 2200 | 2200 | 2200 | 2300 | |

| H | mm | 2680 | 3080 | 3100 | 3120 | 3805 | 3955 | 3830 | 3980 | 3980 | 4360 | 4660 |

5150 |

|

Remarks: Final specifications are subject to contract or agreement.

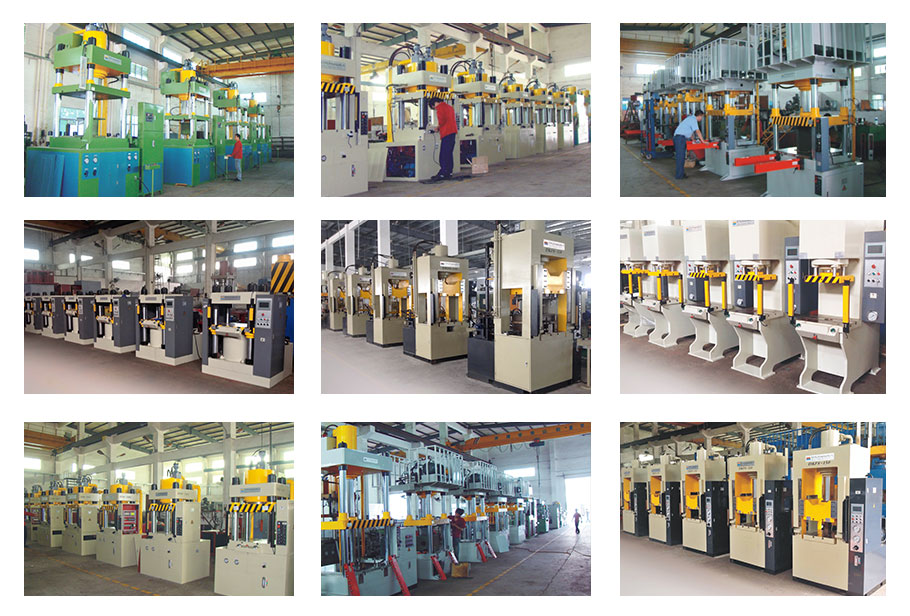

Hydraulic Press Machine with Strictest Quality Certificate Standards

GoodsJakc/Delishi is an ISO 9001:2008 certified company. At GoodsJakc/Delish, everyone accepts that quality is the life of our company. This concept of value rooted deeply in everyone’s mind and has become our commitment to our clients. Every employee takes pride in their work to hold the strictest standard of quality, and to make every hydraulic press machine built with tough quality standards to ensure years of maintenance-free and reliable operation.