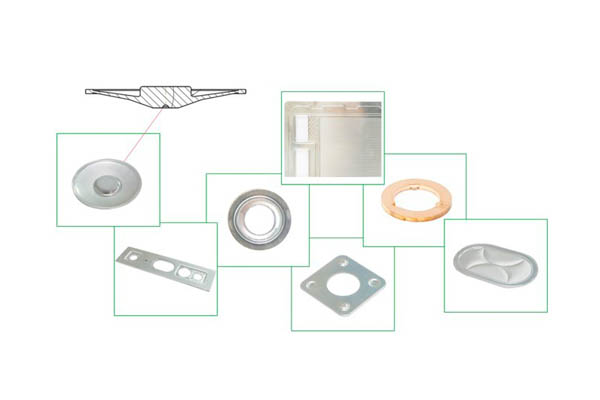

Cold Forging Press for Lithium Power Battery Rupture DiscsUpdate:2024-05-09 Hits:256

Cold forging processing of lithium battery explosion-proof discs. Cold forging refers to various volumetric forming performed below the recrystallization temperature of metal. From the theory of metallurgy, it can be known that the recrystallization temperature of various metal materials is different, Tre= (0.3~0.5) Tmelt. Minimum recrystallization temperature of ferrous and non-ferrous metals. Even at room temperature or normal temperature, the forming processing of lead and tin cannot be called cold forging, but hot forging. However, the forming processing of iron, copper, and aluminum at room temperature can be called cold forging.

These lithium batteries are widely used in electric vehicles, electric trains, electric bicycles, and golf carts. They can also be used in industries such as new energy vehicles, motorcycles, industrial power systems, electric vehicles, and electric bicycles.

The advantages of cold forging press for lithium battery explosion-proof discs include: high product precision, good strength, low material consumption, low energy consumption, low total processing cost, high production efficiency, easy automation, etc.

○ Key Aspects of Cold Forging Press for Rupture Discs

Precision: Forging presses must be capable of high precision to ensure the proper functioning of the rupture discs.

Strength: The discs must be strong enough to withstand normal pressures but break under excessive pressure to prevent battery damage.

Material: Typically, rupture discs are made from materials that can withstand the electrochemical environment inside a battery, like certain stainless steels or nickel alloys.

Size: The presses must be able to accommodate the specific size and thickness required for the battery design.

○ Benefits of Cold Forging for Rupture Discs

Improved Mechanical Properties: Cold forging increases the strength and hardness of the metal.

Enhanced Surface Finish: Produces components with a high-quality surface finish, reducing the need for further processing.

High Production Rate: Cold forging presses can produce parts at a high rate, which is beneficial for mass production.

Material Efficiency: The process generates minimal waste, which is important when working with expensive materials.

○ Considerations for Cold Forging Press Selection

Press Capacity: The tonnage of the press must be suitable for the material and thickness of the rupture discs.

Speed and Control: Variable speed control and precise operation are crucial for the accurate production of rupture discs.

Tooling: Customized dies are necessary for forming the specific shape of the rupture discs.

Maintenance: Regular maintenance is necessary to ensure the longevity and reliability of the press.

○ Safety Considerations

Pressure Calibration: The rupture discs must be accurately calibrated to break at the designated pressure point.

Testing: Rigorous testing is essential to ensure the reliability of the rupture discs in real-world conditions.

Certification: Compliance with international safety standards is crucial for components used in lithium power batteries.

The use of a cold forging press for lithium power battery rupture discs, is a critical aspect of battery safety design. The press must be specifically tailored to produce these components with the required precision, strength, and reliability to ensure effective pressure relief and prevent catastrophic battery failures.

Goodsjack/Delishi Hydraulic Machinery is a leading global provider of Cold Forging Press for Lithium Power Battery Rupture Discs solutions, headquartered 7000㎡ in the Guangdong, China, branch factory 30000㎡ in Hubei, China.