Deep Drawing Press OperationUpdate:2020-07-09 Hits:894

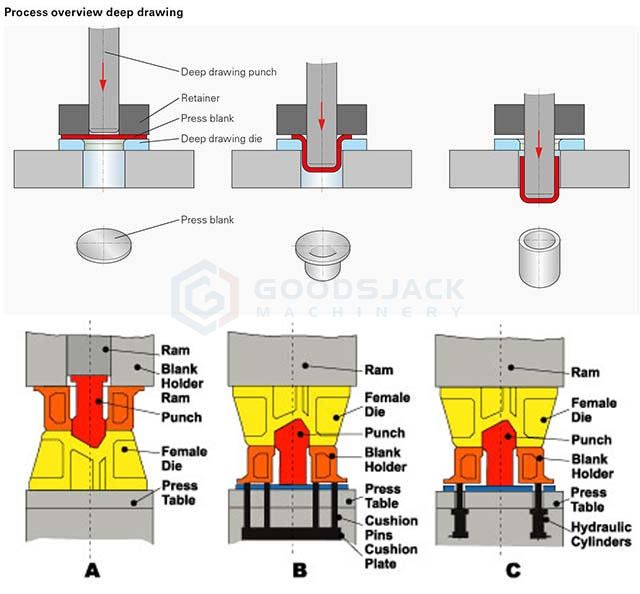

Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch.Deep drawing press working operations are also known as Sheet Metal Operations. The operations performed on the sheets to get the required shape is called Sheet metal operations. The mechanics of deep drawing process is shown in the following drawing. The deep drawing press operation involves five stages bending, straightening, friction, compressions and tension.

Short discussions of these deep drawing press operation stages are given below:

1. Bending

As the application of load starts, the blank is first bent onto the round edge of the die cavity.

2. Straightening

Now, with further increase of the load, the bent part of the blank is straightened in order to sink the annular punch-die clearance. The result is a short, straight, vertical wall formation.

3. Friction

Next, the rest of the blank starts to flow, radially and to sink into the die hole. But the frictional force between the lower surface of blank and upper flat surface of die, try to impede that flow. The magnitude of frictional force drops as the blank metal starts to move.

4. Compression

Now, the blank undergoes compressive stresses. The width of the sector shrinks so that the larger perimeter of the blank can fit into the smaller perimeter of the die cavity.

5. Tension

With further increase in the applied load, almost all the metal blank sinks into the die cavity, thus forming a long vertical wall. The remaining blank part takes the form of a small annular flange. The vertical wall is subjected to uniaxial tension.

Our engineers can design and manufacture the hydraulic press machine according to customers' requirements. Such as linking automation production line. Any interest and requirements, please tell us in advance, then best suitable hydraulic press drawing will be supplied to you!

GoodsJack Hydraulic Deep Drawing Press